Lamination

We connect...

Lamination

We connect...

These days, many products today are not made of just one material. That makes it necessary to permanently connect or weld many different components together.

At HIRI, we have the appropriate technology and the necessary expertise to meet these requirements.

For example, we can provide foam materials with a self-adhesive finish so that they can be permanently bonded to case linings.

Other adhesive tapes only have to serve our customers as assembly aids on their products. This type of self-adhesive is significantly more cost-effective than permanent adhesive.

We will be happy to advise you on the many areas of application.

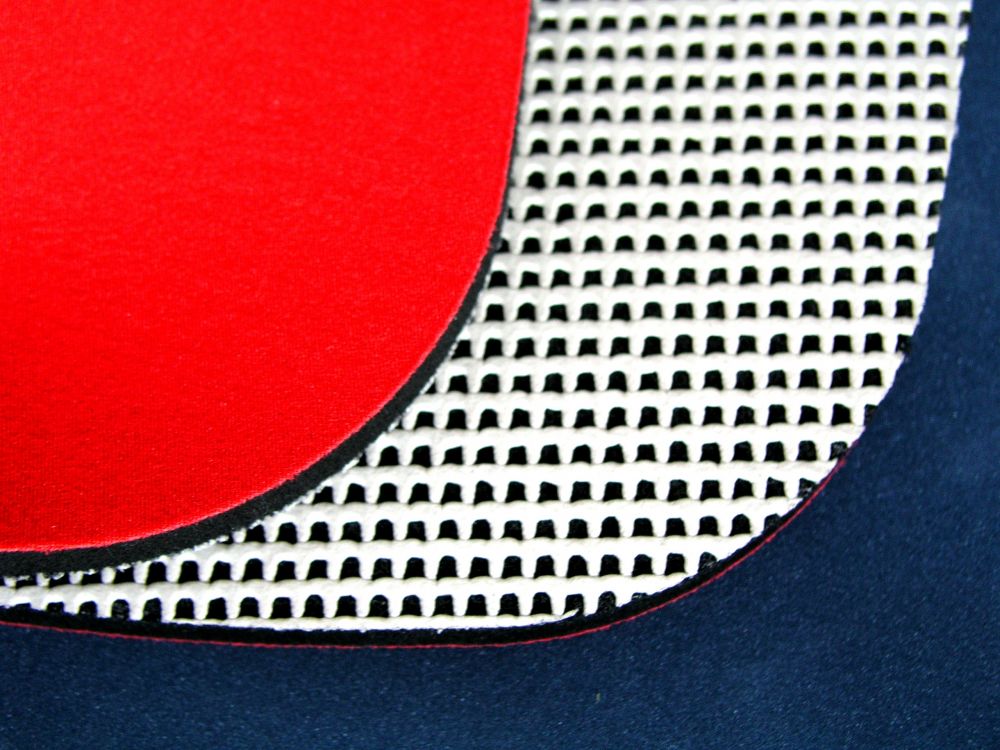

Cellular rubber can be laminated with textiles, for example to make mouse pads.

Or foam rubber can be coated with special films in order to prevent the absorption of moisture, or in the case of preparing products for use with food.

Reference products

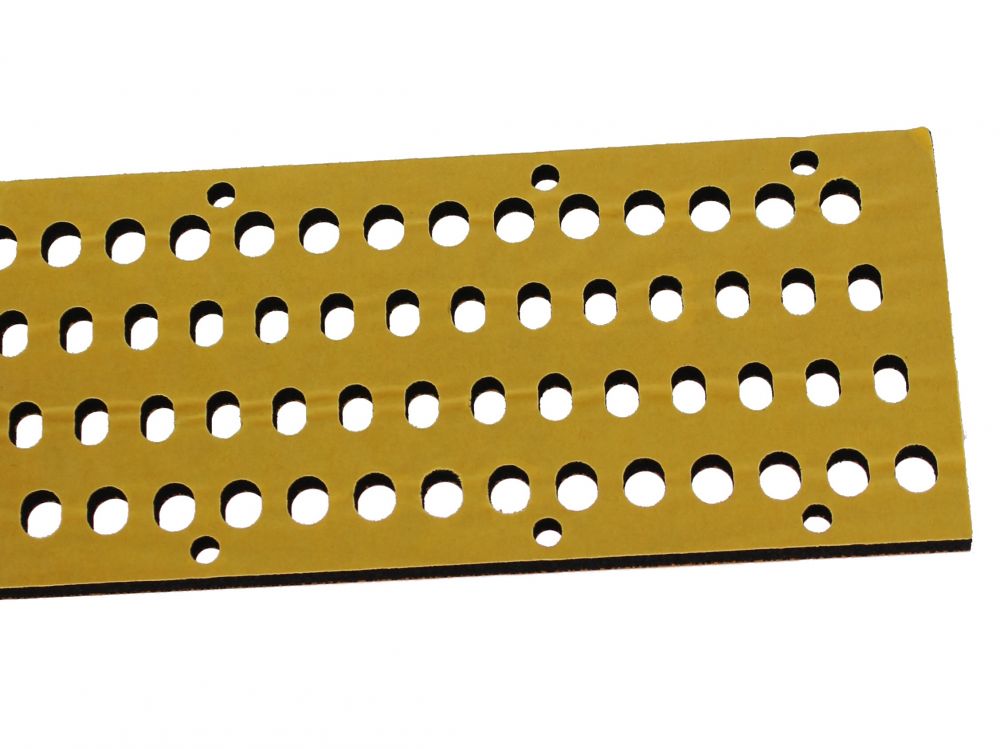

Self-adhesive products

Self-adhesive products

Whether it is intended as an assembly aid or for permanent use – we have the right adhesive for every need. Since every material can be bonded differently and foams in particular are often a great challenge to bond due to their high porosity, we are able to choose from over 100 self-adhesive films. With our expertise and the relevant technology, we have so far been able to make all materials self-adhesive.

Quality Management System

Quality Management System