Water jet cutting

A precise cut

Water jet cutting

A precise cut

HIRI has been shaping products made of PE foam, cellular rubber, foam rubber, sponge rubber and many other materials with the help of water jet technology since 1993.

For the production of water-jet-cut products made of foam materials, rubber and plastic, we have 4 water jet systems, each of which can cut your parts with up to 6 nozzles. A water jet, generated by an approximately 0.1-mm nozzle, through which the water is forced at up to 4000 bar (for comparison: the water runs through your tap at a maximum of 5 bar), precisely cuts the contours of your product.

We can even cut 3-dimensional contours with a water jet system.

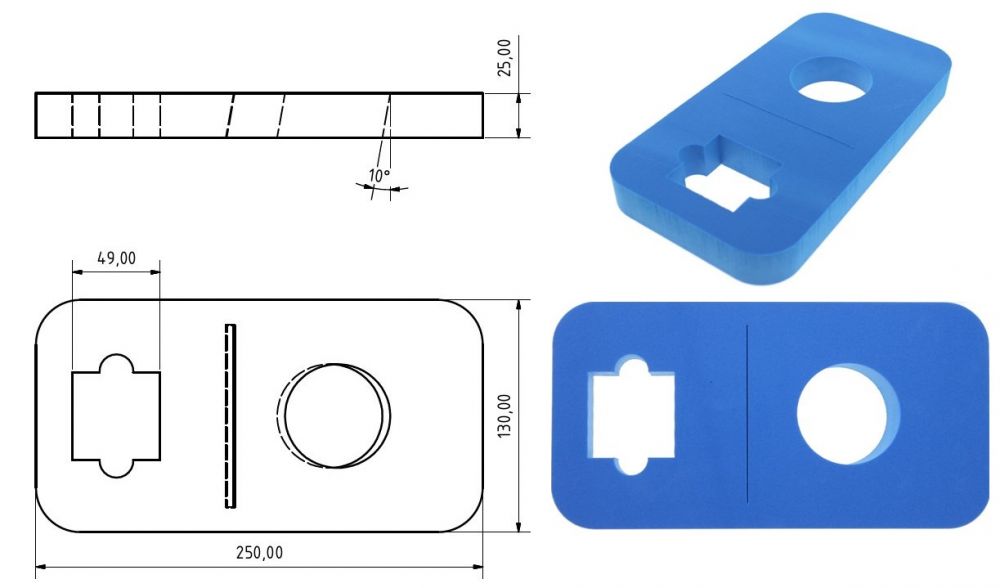

Your water-jet-cut products are designed beforehand at our CAD workstations with AutoDesk software (Inventor/AutoCAD), unless we have already received this data digitally from your design department.

We can then generate the CNC program from this data. The parts can also be nested in such a way to enable the optimal material utilisation.

If a detail on your drawing changes (for example, an additional hole, a different radius, a changed cross-section), that change can be carried out with a few clicks in the file, and the changed product can be water-jet cut straight away.

Even if it would be technically possible for us to cut foams up to a height of 400 mm using water jet technology, due to the scattering jet stream it usually only makes sense to cut foams up to a height of 120 mm, depending on their thickness.

Water-jet cutting on a contract basis is also an option at HIRI, provided that involves foams, rubber and plastics.

3D water jet system

3D water jet system

Water-jet-cut reference products:

Promotional items cut with a water jet

Promotional items cut with a water jet

It is no problem to render extremely small and fine details using water jet technology. The original T-Rex has a height of approximately 60 mm.

Cellular rubber seals cut with a water jet

Cellular rubber seals cut with a water jet

This approximately 20-mm-high seal made of cellular rubber was also created using water jet technology. A bar that is this long is only possible using water jet technology. At this length, punched products would tend to have concave shapes and would not be capable of maintaining the specified tolerances

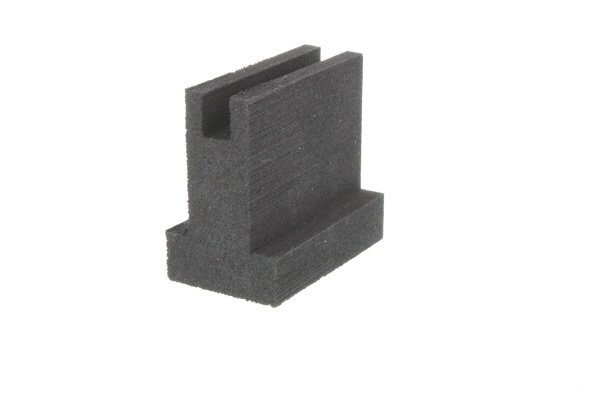

3D water jet part

3D water jet part

For example, inclined or conical cuts can be made using the 3D water jet process.

Quality Management System

Quality Management System